Fulfillment Control: Optimize shipping processes in your Horti-business

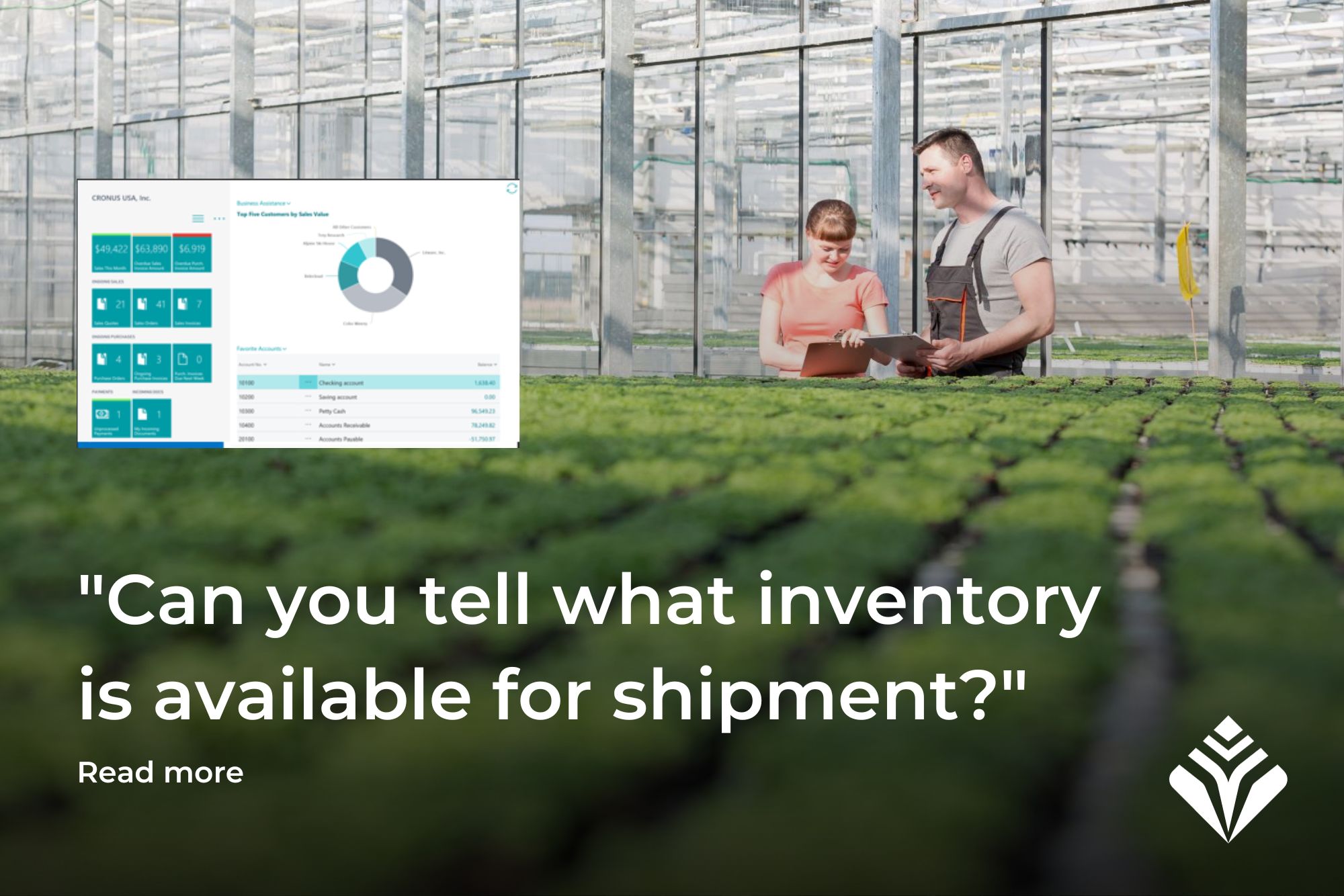

Communication is crucial for shipping, both inside and outside the greenhouse. How can you reduce human errors and cut labor & transportation costs for higher profits?

- Tailor logistics to your business.

- Improve picking and tracking based on inventory

- Automate packing for efficiency.

- Easily create SMART loading plans.

- Track in real-time and share digitally.

01. Fulfilment

From greenhouse to truck, we can help you improve outbound logistics step by step. What is the best place to start? Your business type and challenges will strongly determine what you do. Here are some ideas to help you further. It's up to you to mix & match this. Act small, think big.

.png?width=4564&height=1957&name=MicrosoftTeams-image%20(13).png)

02. Picking

An efficient pick process starts with knowledge about the inventory ready for shipment. What if you are able to register which production batches are (partly) ready to sell and ship, with a simple app? A simple match can be made between orders to sell and the available batches to pick from, taking customers preferences into account. You can start printing pick lists with a proposal where to find the relevant products in the greenhouse, and a next step could be to give people digital pick-orders on their mobile device. With an easy scan action, everyone then can see the status and whether you are on track for the scheduled shipping time frame, so as not to forget the traceability options later on.

- Availability: Begin by knowing the available inventory for shipment.

- Simplified Match: Consider using a mobile app to register and match ready production batches with customer orders, accounting for preferences.

- Enhanced Efficiency: Implement digital pick-orders on mobile devices for real-time tracking, ensuring timely shipping and traceability.

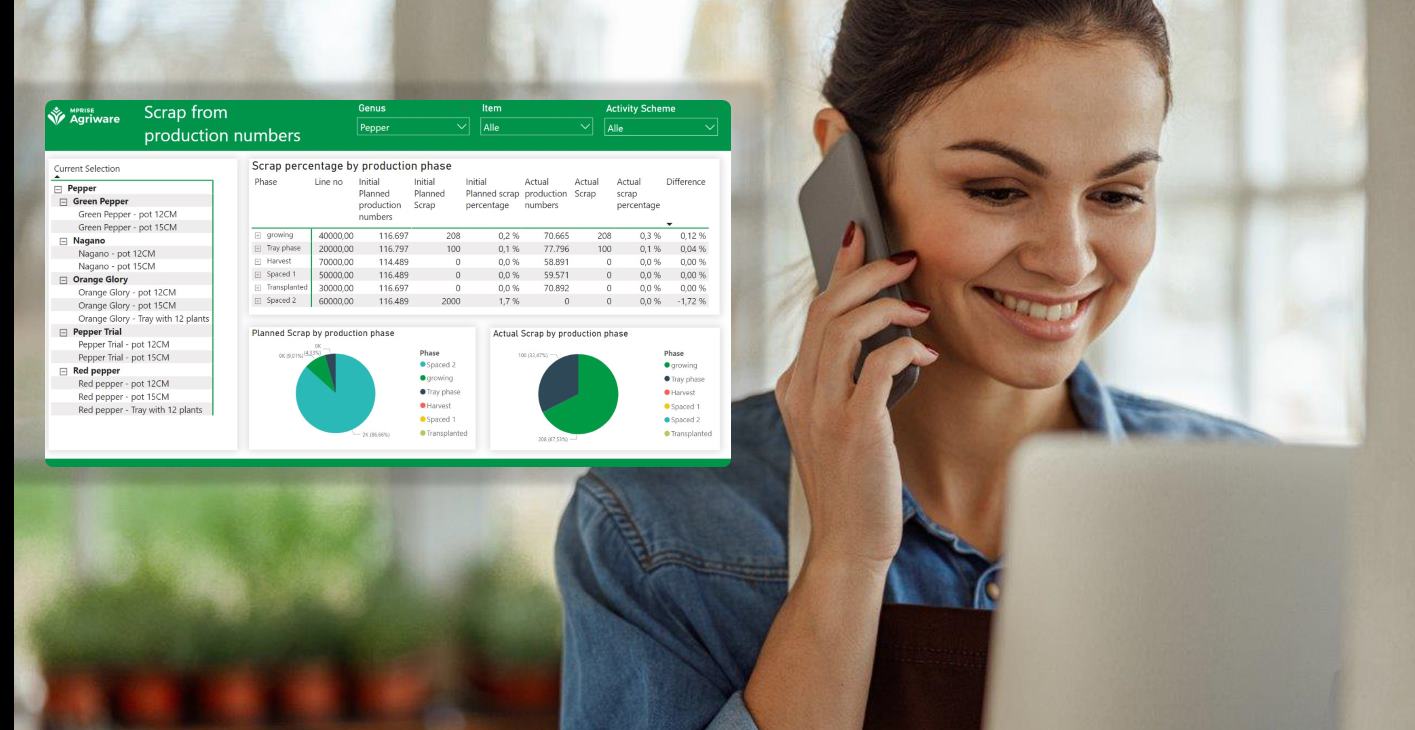

03. Packing

More and more growers provide a service to prep a product for the end customers. This could be from adding a sleeve, label or a fancy ceramic pot to the product to complete composite products. The easy way is to print a packing order and hand it over to the workfloor, but what if you would automate this a bit. You could do batch packing for similar orders, or steer the pick process based on products required for packing. By integrating these processes you will save quite some hassle and walky-talky communication. Next to that, again, everyone is able to see the progress and knows where to look when items are missing for a shipment!

- Customized Product Prep: Many growers offer end-customization services like adding labels, sleeves, or decorative pots to products.

- Efficient Handling: Consider automating the process instead of manually printing packing orders. Options include batch packing for similar orders and aligning picking with packing requirements.

- Enhanced Visibility: Integration streamlines operations, improving progress tracking and minimizing communication hassles, ensuring all items are ready for shipment.

04. Loading

I might have been better off starting with this one, since shipment planning starts with planning how to load your products. It can be quite a challenge to create an optimal loading plan by hand.

- Optimal Loading Planning: Effective shipment planning begins with loading strategy. Creating manual loading plans can be challenging. Agriware 365's load calculation simplifies this task, allowing easy optimization per order, customer, region, or shipping timeframe.

- Streamlined Paperwork: Generate build instructions, load orders, item distribution lists, and other paperwork conveniently from a single platform.

Give your people digital insight

Let your people scan finished orders, loaded carts, racks, so you can track exactly where you stand and inform your customers in real time about the status of their deliveries. Are you willing to look beyond the walls of your own organization? Afterward, send your loading plan digitally to the carrier and exchange status and progress updates. With Microsoft technology, Agriware 365 allows any connection to other systems outside the greenhouse.

Would you be able to tell me if there is any inventory available for shipment?

Summarized

Start with Business Type and Challenges: Determine your starting point in improving outbound logistics based on your specific business type and challenges.

Efficient Picking: Streamline your pick process by registering available inventory for shipment. Match orders with available batches, considering customer preferences. Implement digital pick-orders on mobile devices for real-time tracking.

Automate Packing: Automate the packing process by integrating it with picking, saving time and improving communication. Batch packing for similar orders and product-driven pick processes can enhance efficiency.

Optimal Loading: Use Agriware 365's load calculation to create optimal loading plans easily, considering various factors such as orders, customers, regions, and shipping time frames. Streamline paperwork generation for loading.

Digital Insight: Implement scanning for tracking finished orders, loaded carts, and racks to keep real-time tabs on progress. Share delivery status with customers and digitally exchange loading plans with carriers using Microsoft technology. Agriware 365 facilitates connections with external systems beyond the greenhouse.

Contact our team today!

We help horticultural companies of all sizes with farm / nursery -management software (based on Microsoft). Think of companies of all sizes like Ball Hort, Rijk Zwaan, Anthura, Koppert, Homestead Growers, Green Circle Growers and many more.

Curious what our solution could bring you? Contact us for a free demo by one of our experienced horticulture consultants!